Material testing

1. Glow wire test

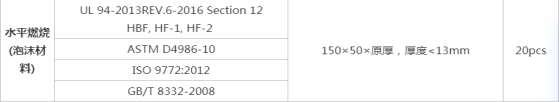

2. Horizontal combustion test

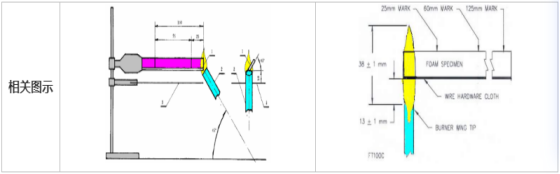

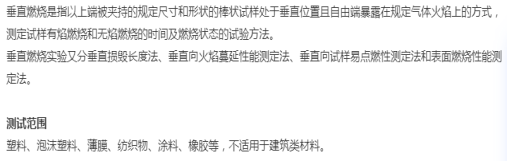

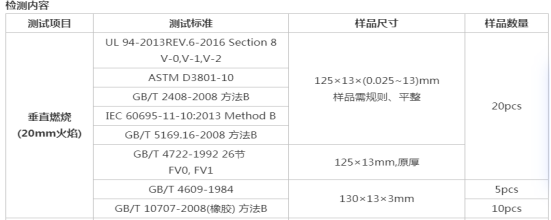

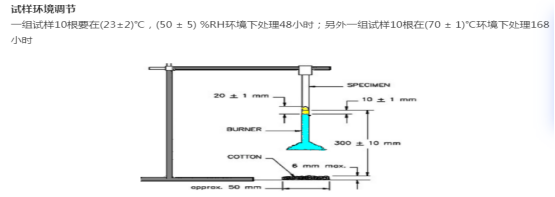

3. Vertical burning test

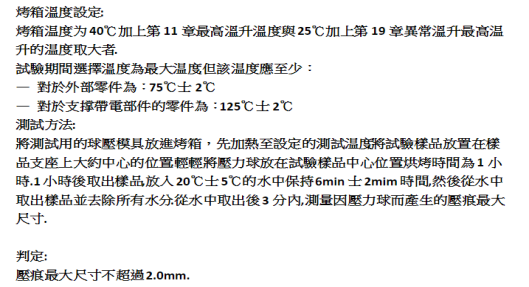

Four, ball pressure test

五、针焰测试

Six, leakage tracking test

purpose:The tracking resistance test is mainly to simulate whether the conductive substances deposited on the surface of the insulating material on the surface of the insulating material of the different polarity live parts of the household appliance product in the actual use are tested to test whether the surface of the insulating material is caused to creep, short circuit and fire. During the use of electrical products, due to environmental pollution, there is dirt and moisture on the surface of the insulating material, which will cause leakage, and the resulting corrosion will damage the insulation performance. The test specified in this standard is an accelerated test that simulates extremely harsh conditions to check whether the insulating material will form leakage traces, so as to distinguish the ability of solid insulating materials to resist leakage tracking in a short time, and to ensure that the product is under specific environmental conditions Safe to use.

Applicable products: Mainly used in the research, production and quality inspection departments of lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical appliances, motors, power tools, electronic instruments, electrical instruments, and information technology equipment. It is also suitable for insulation materials, engineering plastics, Simulation test of electrical connection parts and auxiliary parts industry.

Experimental principle: The tracking test is performed on the surface of a solid insulating material, between platinum electrodes of a specified size (2mm×5mm),-applying a certain voltage and dropping a specified droplet volume at a fixed height (35mm) at regular intervals (30s) Conductive liquid (0.1%NH 4CL), used to evaluate the leakage resistance performance of the solid insulating material surface under the combined action of electric field and damp or polluted medium, and determine its comparative tracking index (CT1) and tracking resistance index (PT1) ) The tracking test is performed on the surface of a solid insulating material, between platinum electrodes of a specified size (2mm×5mm), applying a certain voltage and dropping a specified droplet volume of conductive liquid at a fixed height (35mm) at a time (30s) (0.1%NH 4CL), used to evaluate the leakage resistance performance of the solid insulating material surface under the combined action of electric field and humid or polluted medium, and determine its comparative tracking index (CT1) and tracking resistance index (PT1).

Test standard: The tracking test is GB 4706.1, GB 4207, GB/T6553-2003, IEC60112: 2003 "Measurement Method for Tracking Resistance Index and Comparative Tracking Index of Solid Insulating Materials", UL 746A, ASTM D 3638-92, Simulation test items specified in DIN 53480 standards.

推荐

-

-

QQ空间

-

新浪微博

-

人人网

-

豆瓣