|

|

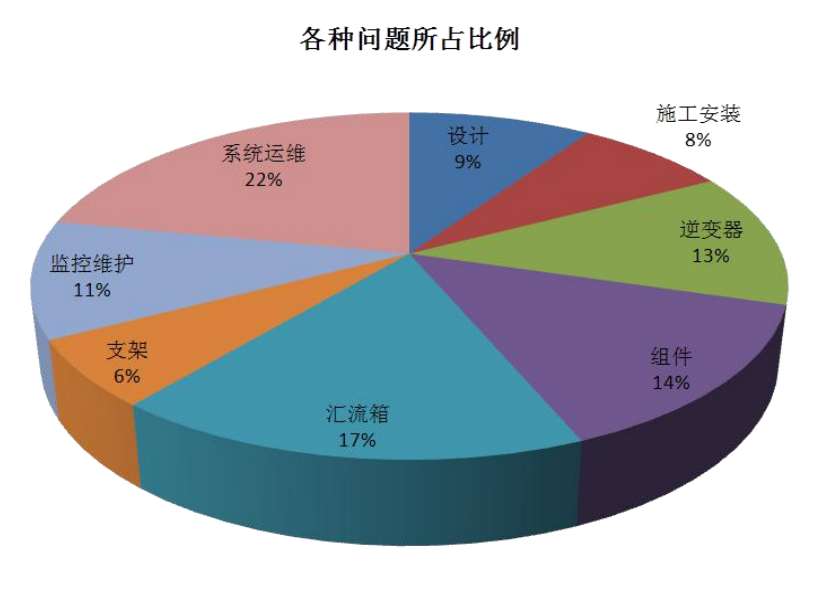

Power station detectionPower station detection - system inspection 1. Documents and materials: project approval, land use license, procurement and contracting contract under grid-connected agreement, design scheme and industrial drawing, technical manual and certification of key parts, completion report, system maintenance manual. 2. Compliance review of power station equipment: components, inverter, bus box, bracket, DC distribution system, monitoring system, etc. 3. Inspection of system electrical equipment: quality of components, electrical wiring, grounding of shock protection, label and identification 4. Inspection of civil construction and support structure: Civil construction and support meet the design requirements, environmental requirements, relevant standards and regulations; The system shall be equipped with corresponding fire fighting facilities 5. Electric construction and design of power station are consistent Power station test - system test Ø key components in the actual operation conditions of performance testing Ø insulation resistance testing Ø ground connection resistance test Consistency Ø electrical installation Ø system electrical efficiency Ø power quality test Ø tracking system test Power station testing - Frequently asked questions Photovoltaic module power generation performance attenuation, reliability reduction: 1) cell 2) hot spot 3) the cracked 4) lightning lines 5) Mixed use of battery Photovoltaic module components and materials: 1) Junction box bypass diode burned 2) EVA delamination and yellowing 3) Backplane bulge PID potential attenuation effect in high humidity environment: 1) A large amount of charge accumulates on the battery surface, aggravating the passivation effect on the battery surface. Lead to the decrease of FF, Jsc and Voc. 2) It is especially obvious in high temperature and humidity environment. High failure rate of photovoltaic inverter: 1) Quality of components 2) circuit breaker 3) filter 4) Other accessories High failure rate of bus box, and not paid attention to: 1) Unreasonable design of fuse protection 2) Unreasonable device selection 3) Poor device quality 4) Non-standard construction and non-standard wiring methods -- increase the later maintenance workload, causing potential safety hazards 5) Equipotential welding connection is not reliable and grounded -- there is a potential safety hazard 6) Improper installation -- affecting the safety of system operation 7) Improper wiring -- easy to cause fire Analysis of Common Problems in power station Detection: Ø construction, installation, affect the quality of the product: (1) Construction organization and management is not in place (2) The technical level of construction personnel does not meet the requirements (3) Assembly and bus box installation does not meet the requirements (4) Insufficient means of project acceptance Ø photovoltaic power station operation maintenance is not in place: (1) The operation and maintenance system does not meet the basic requirements (2) Insufficient technical ability of operation and maintenance personnel (3) Lack of necessary operation and maintenance equipment (4) Lack of necessary means for monitoring the status of power stations

|